Inspection of Bridge Structure:

Inspection and readiness of an inventory are a matter of first importance in any maintenance work. Various inspection types are there for bridge rehabilitation work. Bridge Inspection is significant for checking the physical condition and arranging maintenance exercises. Without legitimate inspection, assessment of the structures’ requirements and arranging maintenance exercises will be ineffective. Routine inspection of the Bridge, approach viaducts, retaining walls, roads and others are significant structures that are fundamental for the safety and serviceability of the equivalent after development. During the inspection, it ought to be the point of the Inspection Engineer to decide the reason for the deterioration.

Also, Read: Rusting of Iron Rebar in Concrete – Special Repairing

Bridge Inspection Objectives:

- The design lifetime of a bridge or flyover is around a hundred years and needs to provide service for enormous traffic volume; in this way, keeping up serviceability and retaining its reliability level during the lifetime deserves high priority from techno-economic considerations.

- The absence of ordinary maintenance of the bridge or flyover may prompt deterioration, preferably prior to its designed life.

- Concrete structures are exposed to many types of environmental influence; in this way, it is crucial to prevent their deterioration.

- The aftereffects and maintenance work is to be precisely and comprehensively recorded, including zero defects, with the goal that a complete history is promptly accessible for all occasions.

Bridge Inspection Engineer Duty:

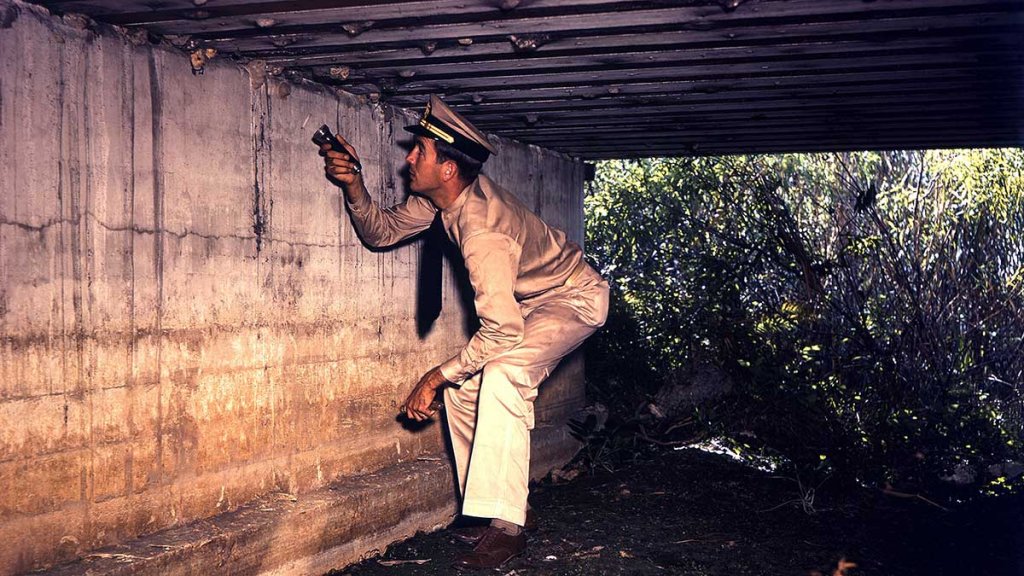

Every part of the works shall be inspected in a series, either by visual inspection or by mechanical assessment, or both as per the need and availability of equipment/instruments and accessibility. The visual inspection has more weightage as it is likely to assess the overall integrity and structural safety. Hence, careful visual inspection is a prerequisite for proper maintenance as this can explain much hidden severe deterioration. Various types of inspection persons engaged and their duties are mentioned below to elaborate the inspection exercises:

- To provide a promise that the structure is structurally safe and fit for its operation as per the design specification.

- Recognize potential causes of trouble at the earliest possible stage and propose corrective and preventive measures.

- To record symmetrically and principally the vital information on which decision can be taken for maintenance work, that is, repairs, strengthening or replacement of the structure.

- Providing feedback data to designers and managers of bridges on those points which are likely to arise maintenance problems and to which required attention is best given during the design and construction stages.

Also, Read: Elastomeric Bridge Bearing – Advantages & Limitations

Bridge inspection Tools:

The tools mentioned below should generally be adequate for different types of inspection, but NDT tests may also be required in case of Special Inspection.

Clip Boards | Torchlight | Straight edge | Camera |

Chalks and markers | Screwdrivers | Plump bob, | Binocular |

Thermometer | Helmet | Spirit level | Pliers |

Inspection mirror | Safety belt | Magnifying Glass | Torque wrench |

Pocket knife | Scrapper and paper | Chipping hammer | Feeler gauge |

Wire brush | Crack meter | Chisel | Calliper |

Also, Read: Blowholes/Surface voids/Bugholes in Concrete Surface

Bridge Inspection Types:

Based on the importance of structure and contribution to the whole project and the safety of traffic movement, the whole inspection procedure shall be divided into three categories. Following are the inspection types

- Routine Inspection of Bridge

- Principal Inspection of Bridge

- Special Inspection of Bridge

Routine Inspection of Bridge:

- Primarily, the routine inspection may be carried out once in two months for the first three years.

- After that, a routine inspection of the existing structure may be carried out once in three months as per the number of distress that happened and approval of higher authorities.

- The routine inspection report will initially depend on the visual examination of the structure using conventional methods and standard inspection tools.

- Under routine inspection, the deficiencies which may lead to an accident or cause huge maintenance and repair costs, if not attended to, would be reported.

Report:

Observations of Routine Inspection should be recorded in an Inspection Register in a standard format to be developed by the organization.

Follow-up Action:

If any critical or significant distress is noticed during a routine inspection, the matter should be reported to the senior-level engineer, and a detailed inspection should be carried out.

Also, Read: Inspection of Bridges – Procedure & General Guidelines

Principal Inspection of Bridge:

- The Principal inspection would involve a more intensive and detailed examination of elements of the structure. The first inspection shall be carried out just after the completion of the project.

- After that, the principal inspection will be carried out at six-month intervals for the first two years and once a year for the remaining period or as the Chief Maintenance Manager decides.

- It will be primarily close visual assessment supplemented by standard instrumented aids.

- The inspection shall be carried out by the Executive Maintenance Manager or Specialist Agencies along with Inspector/ Maintenance Manager against a comprehensive checklist.

- The frequency of the Principal inspections will be reduced in case routine inspection reveals any distress. The Principal inspection shall be stressed, especially in the following:

Report:

Reports of detailed inspection should be accurate and factual. Where there is any uncertainty about the condition of any components or the structure as a whole, it should be clearly mentioned in the report. It should be sufficiently complete to accurately assess the structural load carrying capacity or with other related information based on which detailed analysis of its capacity may be carried out. It should also provide sufficient information for programming of any maintenance or other work if required.

Follow-up Action:

As per the findings of the detailed inspection and test reports, the decision should be taken regarding the further line of action in consultation with the design consultants, including instructions as to whether a particular inspection is called for.

Also, Read: Maintenance of Bridges – General Planning & procedure

Special Inspection of Bridge:

- The special inspection shall be undertaken during unusual occurrences such as accidents, passages of unusual heavy loads, severe earthquakes, floods, significant weaknesses noticed during routine or principal inspections, unusual settlement of foundations and substantial changes in the traffic pattern.

- When other bridges of a similar design and constructed almost at the same time are showing some distress, the Bridge in question shall be subjected to special inspections.

- Such inspections shall require additional testing and the input of the design organizations or experts if necessary.

- This inspection shall be carried out as and when required.

Report:

Observations of Special inspection in case of distresses should be recorded on a separate register called “Special Inspection Register”. As regards the special inspections, which are to be done immediately in case of accidents and severe earthquakes of intensity more than that for which it has been designed, etc., observations should be recorded as a separate note.

Follow-up Action:

As per the findings of special inspection and test reports, the decision should be taken regarding the further course of action in consultation with the concerned authority.

Also, Read: Causes, Prevention and Repair of Concrete Surface Defects

Locations to be Specially Looked for Defects:

|

|

|

|

|

|

|

|

|

|

|

|

Maintenance of structures generally gets neglected because of a misconception that once constructed, it does not need substantial maintenance, particularly in the first couple of decades after construction. However, concrete is a heterogeneous material, and its durability depends mainly on quality control during production, workmanship and condition of exposure. So, to keep the structure in good condition, it has to be inspected routine basis and maintained in a well-planned manner.

Also, Read: Environment Health and Safety(EHS)